Ease of Use

A streamlined, user-friendly interface with guided steps enables fast setup—even for non-technical users.

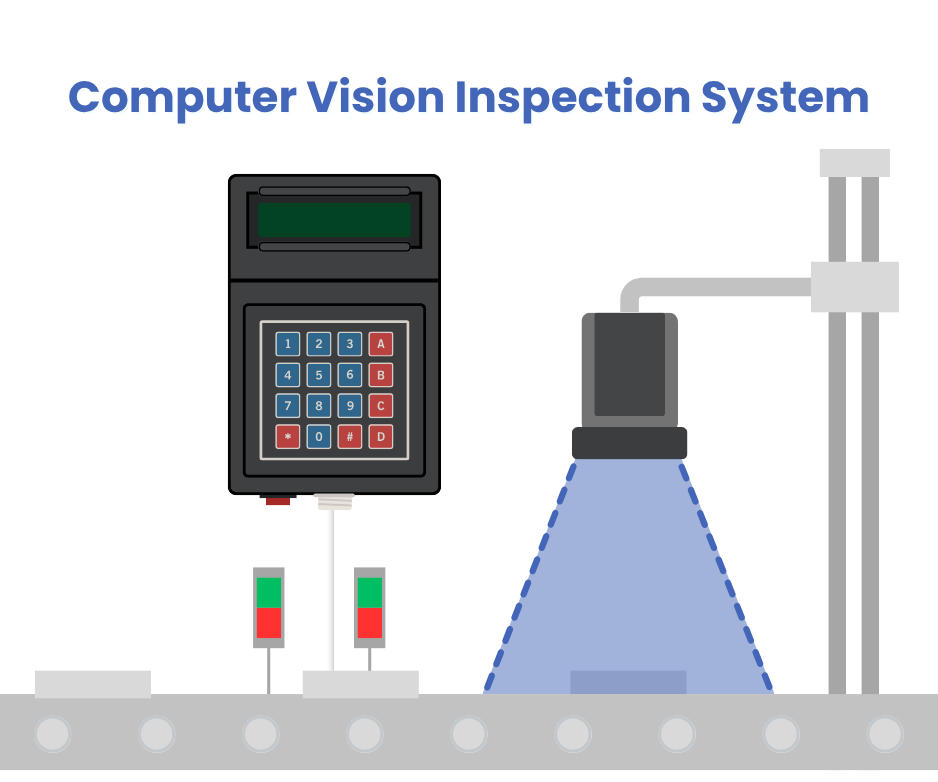

Embsys Agentic Process Automation (APA) leverages AI agents to create flexible, responsive workflows capable of completing Visual Inspection tasks without human intervention. Embsys AI enables out-of-the-box visual inspection and allows you to get started quickly and easily up to the most demanding use cases.

Open the box and take out the Camera and Controller. On to the next step!

It doesn't take long to set up the camera. You can set it up as a stand-alone inspection station.

Connect the components and train AI with 20 good samples of your product and deploy.

Upto

Faster Deployment

Upto

Experts Needed

Upto

Low Rate of TCO

Less than

Go/No Go Decisions

with easy-to-setup hardware, ready-made tools and hardware-agnostic software

with intuitive software backed by online training and suport platforms for on-demand guidance

via instant feedback on image analyses and processing operations

thanks to integrated tools, an intuitive development environment and handy utilities - all designed to shorten problem solving time

with our leading network of OEMs, machine builders, distributors and system integrators

keep costs low with flexible licensing options

A streamlined, user-friendly interface with guided steps enables fast setup—even for non-technical users.

From single-camera to multi-line systems, our platform adapts seamlessly—offering consistent performance.

Extend functionality with prebuilt or custom plug-ins to meet unique inspection requirements.

Hybrid AI approach—on-device and cloud—ensures fast, accurate inspections every time.

Detect presence/absence, completeness, fill levels, and more using high-accuracy vision tools, powered by an easy-to-use graphical interface.

Ensure each product meets quality standards by inspecting location, dimension and consistency during manufacturing and assembly.

With AI-driven learning, go beyond rule-based vision. Train the system with good/bad examples and let it evolve for complex defect recognition.

Accurately read 1D/2D barcodes, QR codes, and labels even on curved or reflective surfaces for inventory and logistics tracking.

Identify and locate parts or products on conveyor belts or assembly lines, even in cluttered or dynamic environments.

Guide robotic arms with visual input for accurate part placement, alignment, and validation of assembly steps.